Updated 9 months ago

Exciting new solar technologies that actually matter (and why they matter)

Written by

Ben Zientara

Find out what solar panels cost in your area

Have you ever seen a news story about a new breakthrough in solar technology that promises to revolutionize the whole world? Promises of new materials and new breakthroughs in efficiency sure make for attention-grabbing headlines.

We’re here to tell you to take the headlines with a grain of salt. Some new technologies are many years (if not decades) away from being viable, while others are not likely to ever come to fruition.

Changes in solar panel efficiency over time mean that we already have amazing, high-efficiency solar technology that is revolutionizing the way we generate and use electricity. Existing technology was enough to lead the International Energy Agency to declare solar the “cheapest source of electricity in history.” And that was back in 2020.

Effectively, the world has what it already needs to bring us to 100% renewable energy. To borrow a phrase from Jigar Shah, we just need to “deploy, deploy, deploy” it.

That said, there are advancements that will verifiably continue to improve and augment our current technologies. Among them are new materials, new ways of building solar panels, and new places to put them. Let’s look at some of the recent advancements, why they matter, and how long it will take for them to have an impact on the world.

Why some breakthroughs matter and others don’t

Technological breakthroughs that matter all have a couple things in common:

They improve an older, proven technology in realistic ways

They are commercially viable or have pathways to viability

There are several ways current solar technology can be improved:

Increased efficiency

Improved material availability and reduced toxicity

Decreased difficulty and/or cost of manufacturing

Improved lifespan

New uses of the technology

The technologies we’ll look at below improve upon existing technology in one or more of these ways. In addition, they’re all either in use or nearly ready to use today.

Silicon heterojunction and tandem solar cells

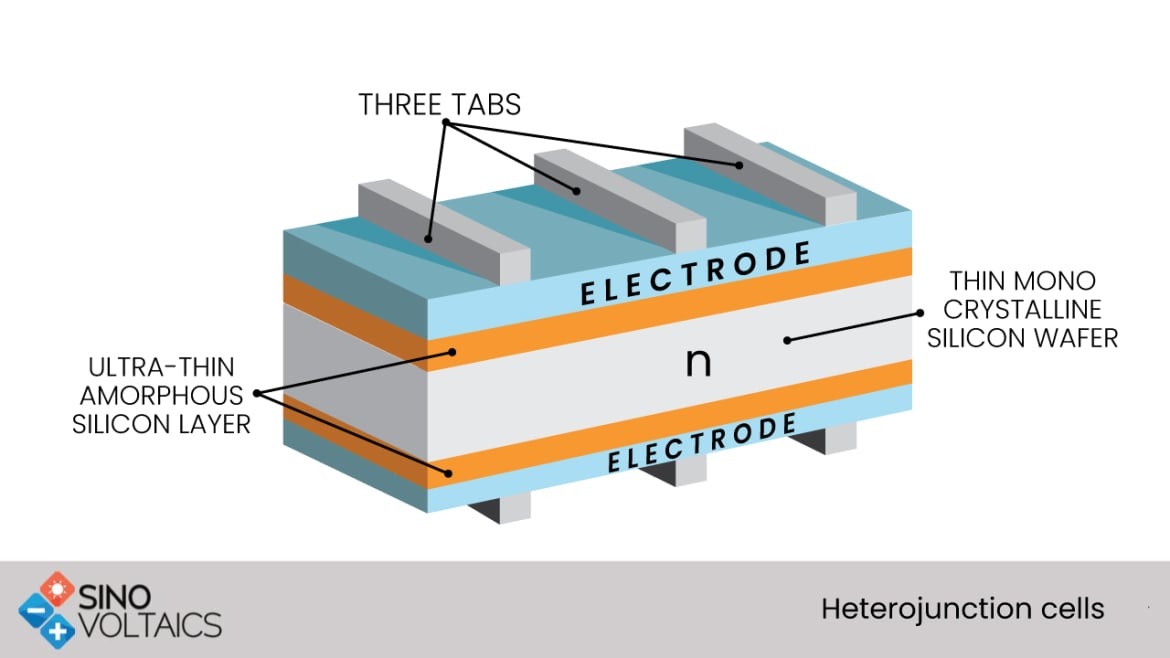

One type of heterojunction solar cell. Image: Sinovoltaics

What problem does it solve?: Increases solar cell efficiency

When will it be on the market?: Now

Is there room for improvement?: Yes

How big of an impact will it have?: Significant

These technologies are not exactly new—in fact, heterojunction cell technology was first invented in the 1970s, and has been used in commercially-available solar panels for decades—but understanding them is vitally important to understanding how solar photovoltaics will be improved in the coming years.

The “hetero” in heterojunction refers to the different layers of semiconductor material sandwiched together to form a solar cell. Silicon heterojunction cells (SHJs) contain a base layer of crystalline silicon coated in thin layers of amorphous silicon.

Each layer can generate electricity from different ranges of wavelengths of light, making the whole cell more efficient than a traditional silicon solar cell, which only has one layer of semiconductor material.

Heterojunction cells have traditionally been more difficult to make than ordinary silicon solar cells, but new advancements in materials will make it more economically viable for manufacturers to switch to the process. One of those advancements is the tandem solar cell, which stacks additional super-thin layers together to make an even more efficient cell.

In order to make tandem solar cells, solar researchers need to look for new materials that can exhibit the necessary properties. These include perovskites and quantum dots, which we cover below.

Perovskites

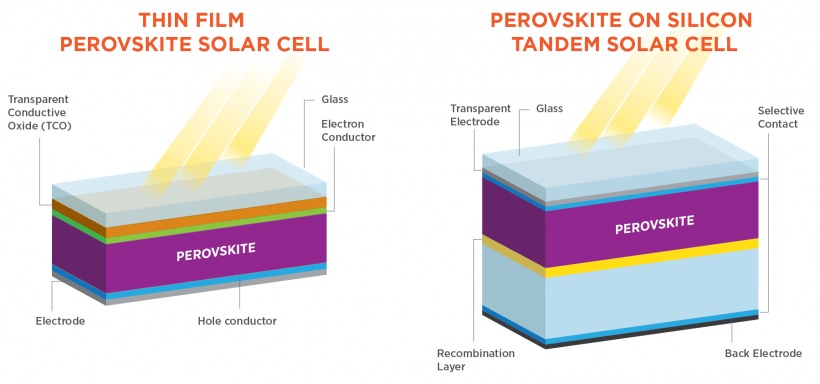

Thin-film vs tandem solar cell structure. Image source: U.S. DOE

What problem does it solve?: Increases cell efficiency and reduces cost and weight

When will it be on the market?: 1-2 years

Is there room for improvement?: Yes

How big of an impact will it have?: Potentially huge

Perovskites are a class of materials first discovered in Russia in 1839. They have a distinctive crystal structure that can form when various different elements combine to form molecules, and many of them are semiconductors.

There are three main reasons perovskites are so interesting to solar researchers:

They are relatively easy to make without special high-heat processes

They can be deposited onto surfaces in simple ways via liquid or vapor

They can be “tuned” to produce electricity from various wavelengths of light, meaning they can capture photons that silicon cells cannot

Unfortunately, perovskites are difficult to keep working for decades, because they break down when exposed to oxygen and moisture. However, advancements have been made in recent years that have greatly improved the stability of perovskite solar cells, and companies are very close to bringing commercial perovskite products to the market.

As mentioned above, the first uses for perovskites will be in heterojunction and tandem solar cells, in which thin layers of perovskite will absorb photons from certain wavelengths of light and silicon layers will absorb other wavelengths.

With their combined capabilities, these cells will exceed the possible efficiency of silicon alone. In the more distant future, perovskites may enable huge reductions in the cost to produce solar cells because the materials are easy to make and can be applied in extremely thin layers to flexible substrates. Read more about perovskite solar cells here.

In the future, perovskites may become viable in their own tandem configurations, potentially stabilized or in combination with quantum dots. But these technologies are still many years away.

Putting panels in different places

Vegetable greenhouse planted under solar photovoltaic panels. Image: jeson - stock.adobe.com

What problem does it solve?: Getting solar deployed

When will it be on the market?: Now

Is there room for improvement?: Yes

How big of an impact will it have?: Medium

One of the biggest challenges when it comes to getting solar installed is figuring out where to put it. At SolarReviews, we’re partial to residential rooftops, but we understand that not all homeowners can benefit from solar. Residential neighborhoods in many places are shady, and roofs should be replaced before installing solar panels, so it’s going to take a while to get solar on enough homes.

Places that can benefit from solar and don’t have a lot of shade include reservoirs, canals, and agricultural land. By building new solar installations in these existing places, we can generate lots of new electricity while improving the existing functions of the spaces underneath the panels.

So-called Floatovoltaics are just what they sound like: floating solar panels. These installations use mounting that is designed specifically to rest on bodies of water, and provides several benefits, including:

Improved water quality and reduced evaporation

Water provides cooling to the solar panels, allowing them to work more efficiently

Can be installed on bodies of water at existing power plants

Image: ungvar - stock.adobe.com

An adjunct to floating solar installations is solar installations on canals. America has thousands of miles of federally-owned canals that provide water for drinking, agriculture, and existing power plants. The benefits of covering those canals with solar panels would result not only in huge amounts of new power generation, but also a major reduction in evaporation in drought-prone areas. It’s a win-win that should be done as soon as possible.

Agrivoltaics is the practice of installing solar panels on farmland in order to both generate electricity and improve outcomes for the farmer. Also called “solar sharing,” agrivoltaics can be used to help improve crop yields, provide and extra use for grazing land, and decrease water used to irrigate.

Solar panels create shade, which is beneficial for crops like tomatoes and corn, and reduces watering requirements for crops like chard, spinach, and lettuce, while preserving yields. Of course, the panels also make electricity that goes toward powering the farm’s buildings and equipment and reducing farmers’ energy bills.

To a lesser extent, things like building integrated photovoltaics and photovoltaic highway noise barriers will provide solar power from places where existing infrastructure will not be displaced.

Final thoughts

Researchers are still studying new breakthroughs in solar technology, and how best to use solar panels on reservoirs, canals, and farmland. One of the best things about being involved in the clean energy sector is getting to see and read about all the interesting advancements that happen every day across the globe.

But the fact remains that the technology that exists today is enough to bring us into a fully renewable, electrified future. How fast that happens is only related to the willingness of governments around the world to prioritize constructing renewable energy generation, energy storage, and transmission systems.

If you’re ready to do a small part to advance renewable energy, use our calculator to see your estimated cost and savings with home solar panels.

Ben Zientara is a writer, researcher, and solar policy analyst who has written about the residential solar industry, the electric grid, and state utility policy since 2013. His early work included leading the team that produced the annual State Solar Power Rankings Report for the Solar Power Rocks website from 2015 to 2020. The rankings were utilized and referenced by a diverse mix of policymakers, advocacy groups, and media including The Center...

Learn more about Ben Zientara